CARBOSPHERE process is about using non-recyclable mixed plastics from North America and transform it into a carbon black concentrate, chemical building blocks to make virgin plastics and mineral concentrates using KWI Polymers’ technology.

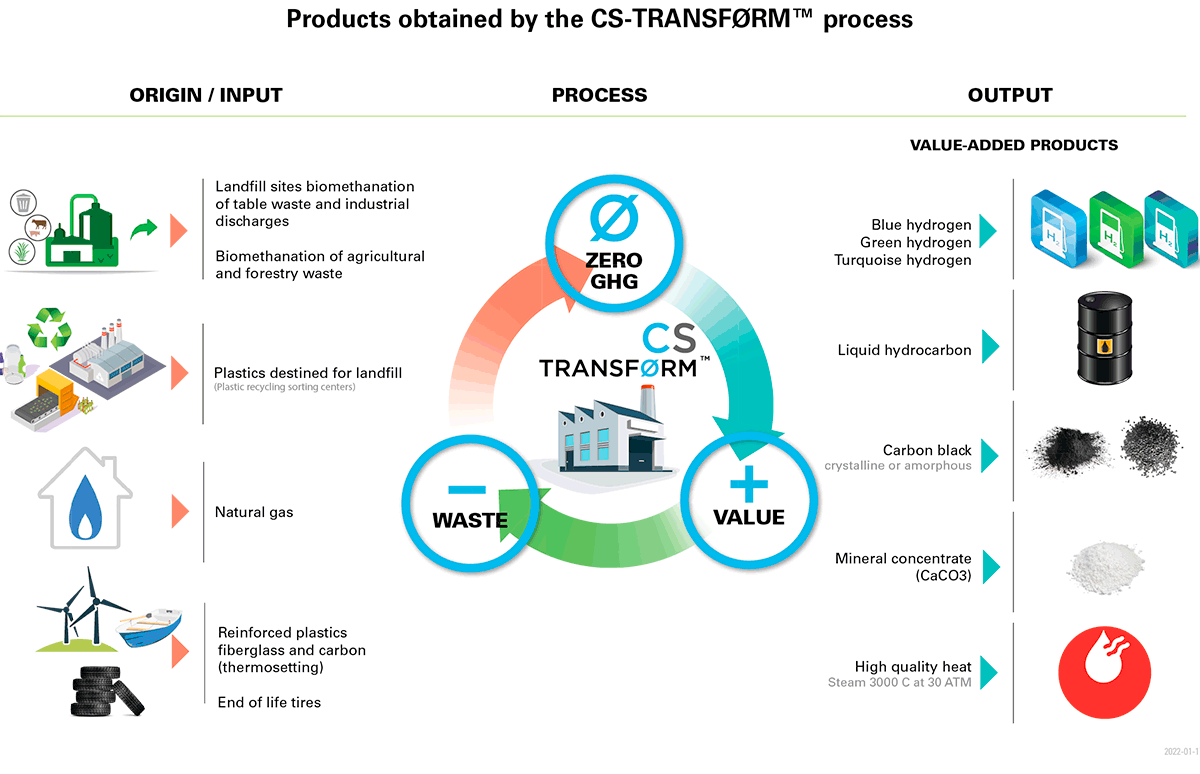

Once the mixed plastics have been dried and sorted to remove major contaminants like glass, metals, papers, etc., this technology will first produce a hydrocarbon-rich gas from which the company could separate the condensable fraction. The condensable fraction (chemical building blocks) could be sold to polymerization plants, refined locally to be able to offer the different sub fractions separately or be used later in the CS-TRANFØRM™ Process. The non-condensable fraction, which is harder to store and transport, will be used immediately as input to produce turquoise hydrogen and a high-quality carbon black. We will also obtain ashes which will be rich in CaCO3 or glass according to the feedstock.

The carbon black powder is then used to make a carbon black concentrate so it could be more easily distributed or exported. Because the CS-TRANFØRM™ Process provides a degree of control over the carbon nanostructure, it can favor carbon black grades aimed towards pure convenience applications such as tires (largest market), or the most valuable grades such as an antistatic product or even a pure conductor (niche markets). In addition, the zero-GHG manufacturing process gives it a definite advantage over competing products.

The hydrogen produced could be sold to local industries as a basic chemical or used either as a clean fuel or to generate green electricity (ideally in a fuel cell).

After the pyrolysis, the plastic fillers recovered in the cinders (ash) can also be recycled. Depending on the plastic waste feedstock, this could be a significant volume. Producing plastic concentrates would be the optimal use of this co-product, but initially cement factories is an easy alternative.

A final co-product, the excess heat generated, provides an opportunity to explore strategic alliances with partners that could exploit this co-product (public heat network, heat to dry wood, heat for green houses, heat to be used in a third-party process, etc.).